Down on the farm...with robots?

Last April, Florida strawberry farmer Gary Wishnatzki had as much as $1 million worth of red, ripe strawberries ready for picking at his farm near Tampa.

Then his crew of temporary seasonal workers suddenly – and unexpectedly – left.

“The crew leader took a couple hundred people and just vanished overnight,” said Wishnatzki, whose family in the 1920s founded what would later become Wish Farms.

"It was an unfortunate situation.”

With no one to do it, the strawberries were never picked. They just withered under the hot Florida sun, despite a going rate of $25 per hour for experienced pickers.

“Strawberries don’t wait,” Wishnatzki added. “They turn red. Then they get rotten.”

According to the industry, it was a situation American agriculture routinely faces: a shortage of workers to get cultivated produce from the farm to your grocery store.

Consequently, Wishnatzki, whose family has been in the business for four generations, now believes it’s time for farming to change and modernize. He has co-founded a company, Harvest CROO Robotics, now attempting to develop robots to work down on the farm.

With robots, those strawberries, he says, would have been picked.

Used often in manufacturing, particularly in tasks involving repetitive movements, robots help in everything today from building cars to sorting online purchases.

Wishnatzki thought it could also help to alleviate the labor challenges common to the U.S. farm industry, not just in cases like the one last April.

“To save the industry, to save the specialty crop sector like strawberries,” Wishnatzki told Fox Business, “We’ve got to automate.”

The question is whether a robot made of aluminum, circuitry, and computer chips can be as discerning and dexterous as a human when picking a delicate piece of fruit.

For example, should a strawberry be picked to today, or a few days from now? Is it already too ripe? And how should the berry be gently plucked without bruising it for the discriminating supermarket shopper?

In a recent Washington Post article, farm worker Antonio Vengas, who fears robots could soon displace farmworkers, said, “People can pick strawberries without hurting them. They know which ones are too little or rotten. Machines can’t do that.”

In fact, Wishnatzki and his engineers believe precisely the opposite.

In much the same way robots, in manufacturing, often complete tasks with more consistency and precision than humans, he suggests the same will happen in this often grinding, hot, backbreaking part of farm work.

“If you tell a crew of 50 people to pick a certain level of ripeness,” Wishnatzki said, “everyone interprets it a little differently. But when you have robots picking, they have the exact same computer program.”

“I think (robots) will actually be able to do it better than humans – and more repeatedly,” he concluded.

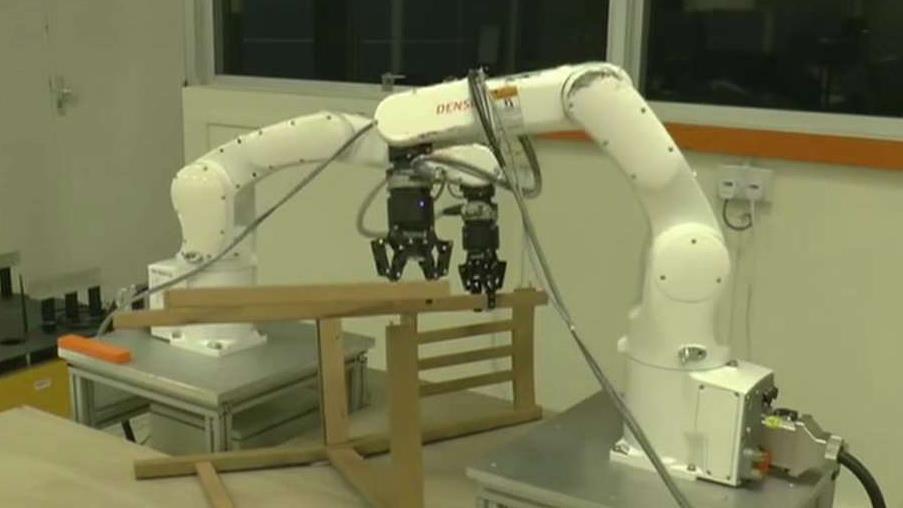

These robotic farmworkers look nothing like Hollywood portrayals of cyborgs or androids that many people often think of.

In reality, the robotic pickers hardly look like “robots” at all. Farm robots don’t march on to the strawberry fields, or fight crime.

The Harvest CROO technology, which has already earned six patents, appears more akin to truck beds that roll atop the rows of strawberry plants.

Underneath, mostly hidden from view, are 16 spinning robotic arms that gather the fruit using cameras, pincers, and “StereoVision Imaging,” a technology that quickly takes hundreds of pictures of each plant to help computers locate and identify the fruit.

“This has only been recently available with [increased] computing power,” Wishnatzki explains. “Ten years ago, you didn’t have the processing power.”

The company will introduce its latest prototype – the Berry 6 – in 2019, which it hopes will begin harvesting at Wish Farms in December.

One machine is expected to do the work of 30 people.

So, what happens, then, to all those non-robots that the machines replace?

A large number of those workers – already dwindling in numbers – come to the U.S. as temporary seasonal workers on H2A visas, says Wishnatzki.

According to the U.S. farming industry, as birth rates in Mexico decline, the Mexican economy further develops, and farming proliferates south of the border as well, staffing American farms at harvest season – even with a visa program – is getting ever more difficult.

In addition, about half of all U.S. farmworkers, according to Labor Department statistics, are working in the country illegally.

“Visas (and visa reform) are a band-aid for a long-term problem,” Wishnatzki adds. “We need to automate. It’s the only path forward.”

And so far, the farmworker unions in the U.S. have not protested. According to news reports, as long as robotic technology helps ease the physical strain on unionized farm workers, and to increase their pay as trained robotics operators, they’re not objecting to the evolution.

Fox Business Network did not immediately receive a response from the United Farm Workers on this issue.

Meanwhile, a familiar situation is playing out at Wish Farms this March.

Due to a shortage of able pickers, strawberries are again being lost to “spoilage.”

“We’re letting some of our least productive fields to go right now, because we can’t keep them all picked,” Wishnatzki said. “Sadly, this is nothing new to us.”

With robots, he believes, those strawberries would not be lost either.

CLICK HERE TO GET THE FOX BUSINESS APP

Yet, this frustration aside, Wishnatzki doesn’t imagine himself going from farmer to full-time robotics developer.

“I’m not likely to give up the family business,” he said. “The robotics company has just been borne out of simple necessity.”