Boeing widens 787 Dreamliner inspections after finding more assembly-line defects

Federal regulators determine defects don’t pose an immediate safety risk, but added scrutiny has slowed deliveries

Boeing Co. has expanded inspections of newly produced 787 Dreamliners after finding a previously disclosed manufacturing defect in sections of the jet where it hadn’t been initially detected, according to industry and government officials.

Boeing engineers and U.S. air-safety regulators agree the newly discovered problem doesn’t pose an imminent safety hazard, the officials said. But the new issue is likely to ramp up a Federal Aviation Administration review of 787 production safeguards sparked earlier this year by other defects, one of these officials said.

The broader quality-control checks, covering the entire fuselage of the planes rather than just certain sections around the tail, are why inspections are taking longer than previously anticipated, the officials said. It also explains why no Dreamliners were delivered in November.

JOURNALISTS BOARD AMERICAN AIRLINES BOEING 737 MAX IN FIRST PUBLIC FLIGHT SINCE GROUNDING

The Chicago-based plane maker disclosed the inspection and delivery delays Dec. 4 without specifying the reasons for them.

The defects in question are spots where the surface of the 787’s carbon-composite fuselage isn’t as smooth as it is should be, a Boeing spokesman said. Such areas can create tiny gaps where fuselage sections are linked together and could lead to premature structural fatigue, which can require extensive repairs. The spokesman said the inspections have pinpointed areas where assembly of portions of the 787 fuselage “may not meet specified skin flatness tolerances.”

The defects mark the fourth assembly-line lapse affecting Boeing’s popular family of wide-body jets that has come to light in as many months. Other than May, after the Covid-19 pandemic roiled airline operations and forced the plane maker to briefly shut down production facilities, November was the only month since 2013 without a Dreamliner delivery, according to an analysis of delivery data.

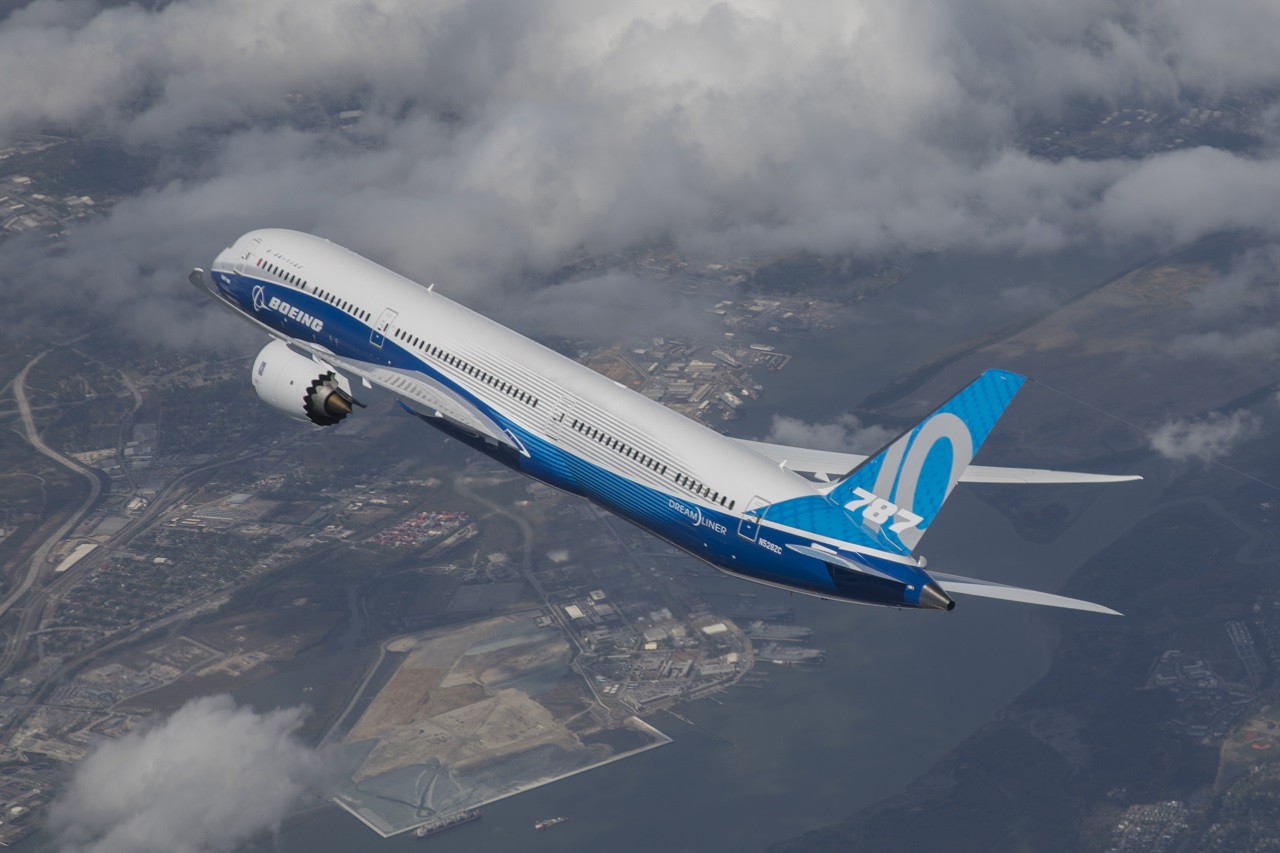

Boeing has rolled out the first 787-10 Dreamliner built for Singapore Airlines at its Final Assembly facility in North Charleston, South Carolina. The plane is seen here in the factory. (Josh Drake photo via Boeing)

The company found the latest issue through strengthened quality-assurance practices over the past year, when other defects had been identified, the Boeing spokesman said. And he said the company has asked suppliers to perform similar checks. “These findings are part of Boeing’s review of assembled 787 aircraft to ensure each meets our highest quality standards prior to delivery to customers,” he said.

The FAA, which has been considering actions to mitigate the problems by potentially issuing safety directives, on Sunday released a statement saying the agency regularly engages with Boeing on “continued operational safety and manufacturing oversight processes to appropriately address any issues that might arise.”

Under pressure from the FAA, Boeing also has stepped-up internal manufacturing controls focusing on other lapses ranging from inspection paperwork problems to debris mistakenly left behind by assembly-line workers inside 737 MAX jetliners and military tankers.

SOUTHWEST CEO SAYS SOFTWARE ISSUES IN BOEING MODEL THAT CRASHED TWICE HAVE 'EASILY BEEN ADDRESSED'

The wide-body passenger jets, which Boeing first delivered in 2011, have an excellent safety record and are frequently used on long international routes. If found on planes already carrying passengers, the latest defect can be addressed during comprehensive maintenance checks that are required as the jets age, some of the officials familiar with the matter said.

Delivery delays threaten to add to Boeing’s financial strain as it struggles with fallout from the pandemic, which has sapped global demand for air travel and passenger jets. Boeing Chief Financial Officer Greg Smith has said Boeing expected to continue working to clear its growing inventory of undelivered Dreamliners through next year.

GET FOX BUSINESS ON THE GO BY CLICKING HERE

Earlier this year, Boeing disclosed the skin-smoothness defect near the rear of the planes, as well as improperly sized shims—or parts used to fill small gaps where the fuselage sections are joined together. It wasn’t immediately clear how many planes have been found with the skin-smoothness defects in additional locations, but officials familiar with the matter said instances appeared relatively isolated.

Boeing engineers previously determined that when the defects involving skin smoothness and shim size both occur in the same location, the result can be tiny imperfections creating a potential hazard such as a cracking in the fuselage under extreme flying conditions. Boeing in August took the unusual step of voluntarily grounding eight aircraft in airlines’ fleets for immediate repairs.

Those earlier problems prompted the FAA to start reviewing quality-control lapses in Boeing’s 787 production stretching back almost a decade.

CLICK HERE TO READ MORE ON FOX BUSINESS

Boeing also previously identified a third quality-control lapse affecting the horizontal stabilizer, a movable, winglike panel in the tail.

Earlier this month, Mr. Smith disclosed Boeing’s intention to further cut 787 production next year because of weak demand and a growing backlog of parked planes.

Boeing, which has been producing around 10 Dreamliners a month, as of early December had 53 built but undelivered 787s that had been in its inventory for an average of about five months, according to aviation-research firm Ascend by Cirium.

Mr. Smith said the monthly 787 production rate would remain below Boeing’s target of 10 before slowing to five in May at its plant in North Charleston, S.C. Assembly of 787s is set to end at a Seattle-area Boeing facility.

The 787 manufacturing issues are unrelated to design flaws in a flight-control system that kept the global fleet of 737 MAX jets grounded for nearly two years. The plane models are built in separate facilities.

—Doug Cameron contributed to this article.